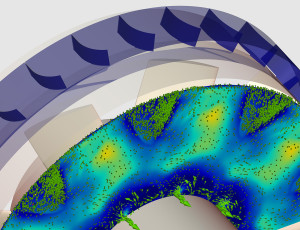

AGS Consulting, LLC has developed a three dimensional CFD capability based on OpenFOAM. The resulting CFD flow-field simulations provide an insight into the flow-field features responsible for reducing fan efficiency. Parametric variation of casing or impeller geometry may then be used to provide an insight into the effectiveness of changes in geometry that are possible within the limits of existing manufacturing processes or tooling. This parametric approach achieves significant improvements in fan efficiency without the need for major changes in jigs, tooling or fixtures.

AGS Consulting, LLC has developed a three dimensional CFD capability based on OpenFOAM. The resulting CFD flow-field simulations provide an insight into the flow-field features responsible for reducing fan efficiency. Parametric variation of casing or impeller geometry may then be used to provide an insight into the effectiveness of changes in geometry that are possible within the limits of existing manufacturing processes or tooling. This parametric approach achieves significant improvements in fan efficiency without the need for major changes in jigs, tooling or fixtures.

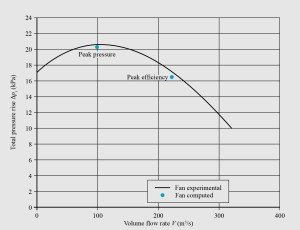

The use of three-dimensional CFD to provide an insight into the flow-field physics relies on an accurate simulation of the blade-to-blade flow-field. The three-dimensional CFD is initially used to predict overall fan performance at duty points of specific interest. In the example to the right fan performance is predicted at peak efficiency and peak pressure duty points. Once overall performance is predicted within the uncertainty of the measured performance, we may assume that the flow-field though the fan is also predicted accurately.

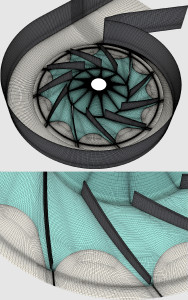

Predicting the blade-to-blade flow-field though any fan is challenging, however when modelling centrifugal fans, one cannot reduce the computational effort by modelling a single blade passage with imposed periodic boundary conditions. Centrifugal fan simulations must be full rotor simulations to account for the interaction between the impeller and housing within which it is situated. As a consequence of housing geometry, the flow-field through any single blade-to-blade passage is inherently periodic and consequently, requires more computational effort than an axial fan single blade passage flow-field simulation.

Additionally, the flow-field through a centrifugal fan impeller is highly three-dimensional and if the blades are rolled flat plate, separated flow regions typically characterize the blade-to-blade flow-field. Therefore, the flow-field through a centrifugal fan is inherently both periodic and unsteady, making an unsteady prediction of the flow-field necessary to adequately model the flow-field physics.

Unsteady predictions of the flow-field require both dense and well-conditioned computational mesh plus more computational power than is typically available to commercial or industrial fan manufactures. AGS Consulting, LLC uses a high performance computer cluster for large computational projects. Consequently AGS Consulting, LLC is able to undertake the unsteady three-dimensional CFD analysis that is required for real insight into the flow-field.